Wire Thread Insert Repair Kit 10-24

(Pack of

1.0)

• Helically-wound thread repair – universally accepted and most cost-effective method of thread repair

• Manufactured from precision cold-formed 18-8 (Type 304) stainless steel

• Kits contain tap, inserts, installation tool, tang removal tool (select kits) and instructions, packaged in a sturdy and convenient storage box

• Inserts compensate for pitch and angle errors and share the load over more of the thread for stronger assemblies

• Tensile strength of at least 200,000 PSI

• Wide effective temperature range: –275°F to +774°F (–170°C to +412°C)

Fix-A-Thred® Insert Installation Instructions

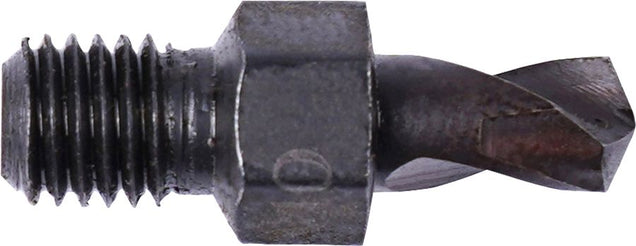

Drill to clear out the damaged thread (if necessary).

Thread insert tap supplied. Tap thread should match up with bolt.

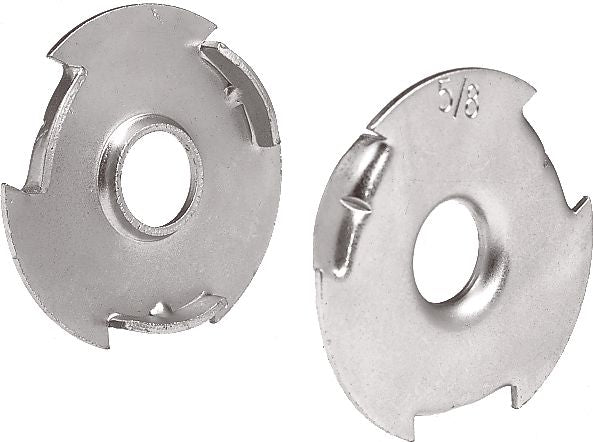

Wind insert in with light downward pressure until 1/4 to 1/2 turn below surface, driving tang towards bottom of the hole.

Remove tool and sit back on top of tang. Tap down sharply. Do not try to twist tang off. For large fine threads, use long nose pliers and pull tang out.

To insure proper installation of inserts, always use the correct and corresponding tools.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

Frequently Bought Together

Cryobit #21 Dia. T-Bit, 2-1/8" Long Shank Length, 1/4"-28 Thread

Couldn't load pickup availability

Cryobit #30 Dia. T-Bit, 1-1/4" Short Shank Length, 1/4"-28 Thread,Bulk

Couldn't load pickup availability

Cryobit 3/32" Dia. T-Bit, 9/16" Stubby Length, 1/4"-28 Thread

Couldn't load pickup availability

Throttle Ball Joint with Spherical Bearing 3/4-16

Couldn't load pickup availability

Throttle Ball Joint with Spherical Bearing 3/8-24

Couldn't load pickup availability

Throttle Body Injector Repair Harness

Couldn't load pickup availability

Lok-Rite M12 x 1.75 Stainless Steel Threaded Insert

Couldn't load pickup availability

Heavy-Duty Locking Thread Insert 3/4-16

Couldn't load pickup availability

Wire Thread Replacement Insert M18-2.5

Couldn't load pickup availability

Fiber Disc Back-Up Pad Retaining Nut 5/8-11 Arbor

Couldn't load pickup availability

Wire Wheel Metal Adapter 1/2"

Couldn't load pickup availability

Twist-On Holding Pad 30000rpm 2"

Couldn't load pickup availability

Spark Plug Thread Repair Kit M14 x 1.25

Couldn't load pickup availability

Wire Thread Insert Repair Kit 1/4-28

Couldn't load pickup availability

Wire Thread Insert Repair Kit M10-1.5

Couldn't load pickup availability

Product Description

• Helically-wound thread repair – universally accepted and most cost-effective method of thread repair• Manufactured from precision cold-formed 18-8 (Type 304) stainless steel

• Kits contain tap, inserts, installation tool, tang removal tool (select kits) and instructions, packaged in a sturdy and convenient storage box

• Inserts compensate for pitch and angle errors and share the load over more of the thread for stronger assemblies

• Tensile strength of at least 200,000 PSI

• Wide effective temperature range: –275°F to +774°F (–170°C to +412°C)

Fix-A-Thred® Insert Installation Instructions

Drill to clear out the damaged thread (if necessary).

Thread insert tap supplied. Tap thread should match up with bolt.

Wind insert in with light downward pressure until 1/4 to 1/2 turn below surface, driving tang towards bottom of the hole.

Remove tool and sit back on top of tang. Tap down sharply. Do not try to twist tang off. For large fine threads, use long nose pliers and pull tang out.

To insure proper installation of inserts, always use the correct and corresponding tools.

Technical Specifications

| Item#: | 53822 |

|---|---|

| Type | Insert Repair Kit |

| Size | 10-24 |

| Recommended Drill Size | 13/64 " |

| Number of Pieces | 17 |

| UNSPSC #: | 27112810 |

| TAA Compliant: | Yes |

Product Restrictions

California Proposition 65: WARNING: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov