Drop-In Anchor High Strength 1/2-13 x 3-5/8"

(Pack of

10.0)

• When used with adhesive anchoring compound, these anchors provide a superior concrete anchoring system and withstand more seismic vibration loading than most mechanical anchors

• Adhesive anchoring compound adheres to the entire length of the anchor body for excellent ultimate tensile strength

• Through-hole installation is ideal for in-place fastening applications – no need to move equipment or fixtures

• Can be used with hex bolts, mushroom head bolts and threaded rod with nuts

• The use of anchoring epoxy/compound is required

NOTE: Allow anchoring compound to fully cure before applying maximum load.

• Use for equipment mounting, conveyor and rack installation, stadium seating and highway construction

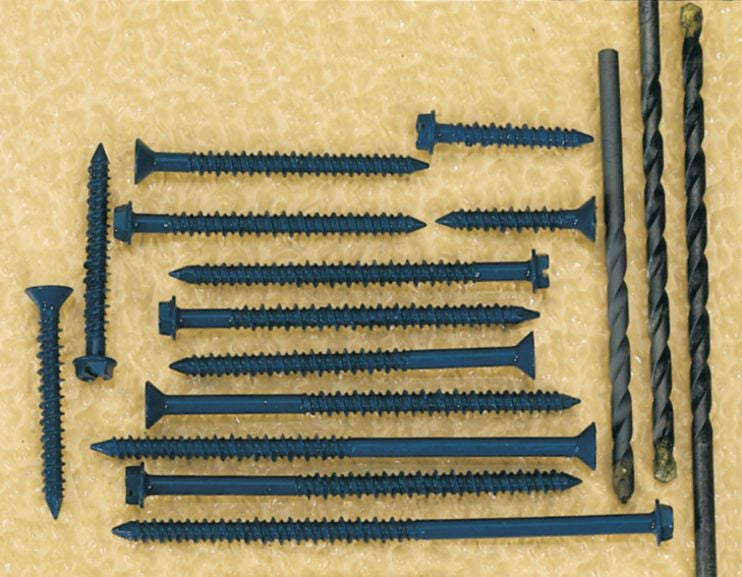

1. Select the proper size drill bit. Drill the hole perpendicular to the work surface.* To assure full holding power, do not ream the hole or allow the drill to wobble.

2. Clean hole with compressed air and a nylon brush.* Dust and debris left in hole will significantly reduce the holding capacity of the anchor.

3. Inject adhesive anchoring compound into hole to approximately 1/3 to half full.

4. Choose a fastener equal in length to the thread depth plus the material depth. Thread fastener into anchor so that offset is equal to the thickness of material to be fastened. Insert anchor into hole to shoulder with slight twisting motion.

5. Drive anchor flush to the surface with several sharp hammer blows to the head of the fastener.

6. Allow adhesive anchoring compound to cure prior to applying maximum load.

Drill size equals anchor body diameter

*Always wear safety glasses. Use only solid carbide-tipped drill bits meeting ANSI B94 diameter standards.

Couldn't load pickup availability

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov

Frequently Bought Together

Light-Medium Duty Anchor Assortment 555Pcs

Couldn't load pickup availability

Wallboard Anchor Assortment 1125Pcs

Couldn't load pickup availability

Masonry Anchor Assortment 243Pcs

Couldn't load pickup availability

Drop-In Anchor Steel 1/2 x 2"

Couldn't load pickup availability

Drop-In Anchor High Strength 5/16-18 x 2-7/16"

Couldn't load pickup availability

Drop-In Anchor High Strength 3/4-10 x 6-1/2"

Couldn't load pickup availability

Hex Cap Screw Grade 8 Alloy Steel 5/8-18 x 2-1/2"

Couldn't load pickup availability

U-Drive Screw Round Head #6 x 1/4"

Couldn't load pickup availability

U-Drive Screw Round Head #4 x 1/4"

Couldn't load pickup availability

Cable Tie Screw Mount #10 Screw Black

Couldn't load pickup availability

H3 Halogen Miniature Bulb 70W 24V

Couldn't load pickup availability

Cable Tie Screw Mount #8 Screw White

Couldn't load pickup availability

Product Description

• When used with adhesive anchoring compound, these anchors provide a superior concrete anchoring system and withstand more seismic vibration loading than most mechanical anchors• Adhesive anchoring compound adheres to the entire length of the anchor body for excellent ultimate tensile strength

• Through-hole installation is ideal for in-place fastening applications – no need to move equipment or fixtures

• Can be used with hex bolts, mushroom head bolts and threaded rod with nuts

• The use of anchoring epoxy/compound is required

NOTE: Allow anchoring compound to fully cure before applying maximum load.

• Use for equipment mounting, conveyor and rack installation, stadium seating and highway construction

1. Select the proper size drill bit. Drill the hole perpendicular to the work surface.* To assure full holding power, do not ream the hole or allow the drill to wobble.

2. Clean hole with compressed air and a nylon brush.* Dust and debris left in hole will significantly reduce the holding capacity of the anchor.

3. Inject adhesive anchoring compound into hole to approximately 1/3 to half full.

4. Choose a fastener equal in length to the thread depth plus the material depth. Thread fastener into anchor so that offset is equal to the thickness of material to be fastened. Insert anchor into hole to shoulder with slight twisting motion.

5. Drive anchor flush to the surface with several sharp hammer blows to the head of the fastener.

6. Allow adhesive anchoring compound to cure prior to applying maximum load.

Drill size equals anchor body diameter

*Always wear safety glasses. Use only solid carbide-tipped drill bits meeting ANSI B94 diameter standards.

Technical Specifications

| Item#: | 50198 |

|---|---|

| Diameter | 1/2 " |

| Overall Length | 3-5/8 " |

| Thread Pitch | 13 tpi |

| Thread Depth | 1 " |

| Type | Chemical Drop-In Anchor |

| Thread Diameter | 1/2 " |

| Drill Size | 5/8 " |

| Hole Depth | 4-1/8 " |

| UNSPSC #: | 31162101 |

| TAA Compliant: | No |

Product Restrictions

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov