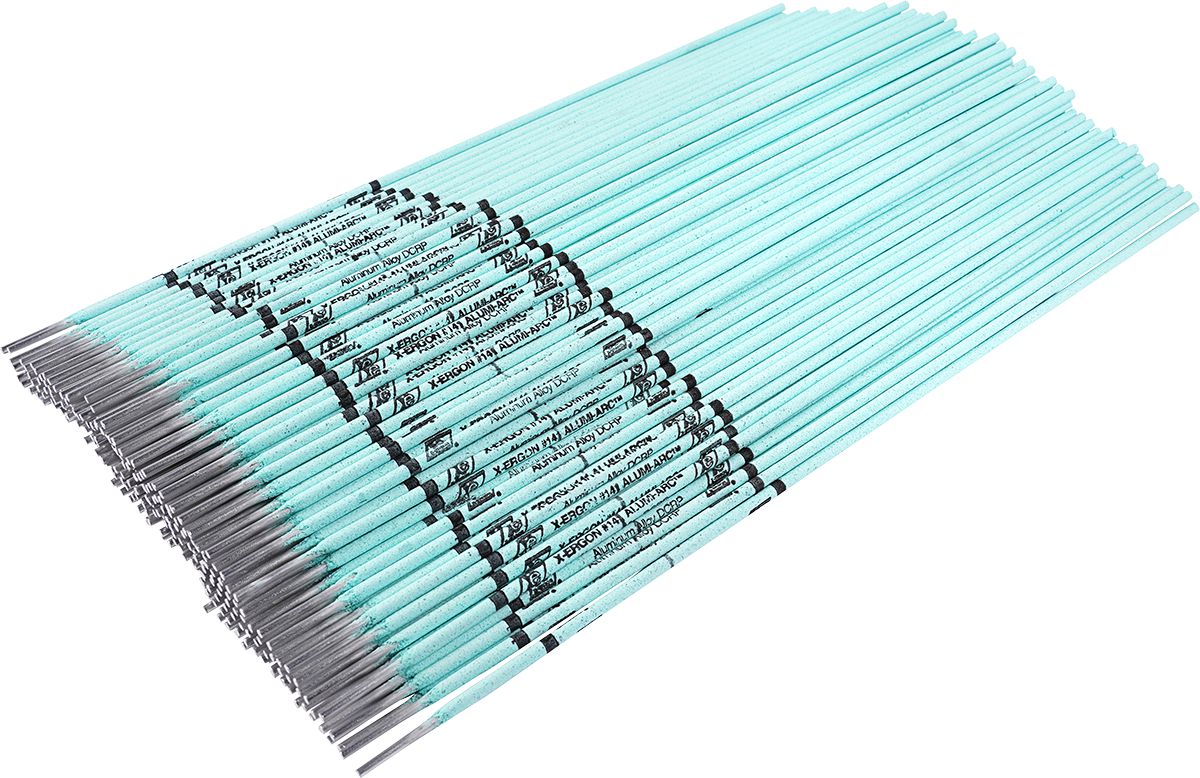

510 Aluminum Stick Rod Electrode 1/8"

(Pack of

2.0)

Highly versatile alloys for all weldable types of aluminum including sheet, forgings, extrusions and castings.

Superior Advantages

• Stable, quiet arc with no undercutting

• Good corrosion resistance

Tensile Strength: 35,000 PSIPolarity: DC Reverse

Usage ProcedureMaintain the shortest arc possible, using DC reverse polarity only. On large heavy sections, preheating to 400°F (204°C) will produce faster, flatter deposit with no splatter. Electrode should be held almost perpendicular and use a rapid stringer or weaving technique with a backwhip at the crater. Bevel pieces 75° on sections 1/8" (3.2mm) or thicker.

Couldn't load pickup availability

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov

Frequently Bought Together

556 Aluminum MIG Welding Wire 0.03"

Couldn't load pickup availability

510 Aluminum MIG Welding Wire 3/64"

Couldn't load pickup availability

141 Aluminum Stick Electrode 1/8

Couldn't load pickup availability

Paint Marker Green

Couldn't load pickup availability

Sheet Metal Drill Bit Alloy Steel 1/8"

Couldn't load pickup availability

Radiator Grille Nut M4.2-1.41

Couldn't load pickup availability

Welding Container Drawer 19 - Welding PPE

Couldn't load pickup availability

Welding Container Drawer 22 - Cryotaps

Couldn't load pickup availability

Welding Container Drawer 11 - X-Cut Exothermic Cutting System with Rods

Couldn't load pickup availability

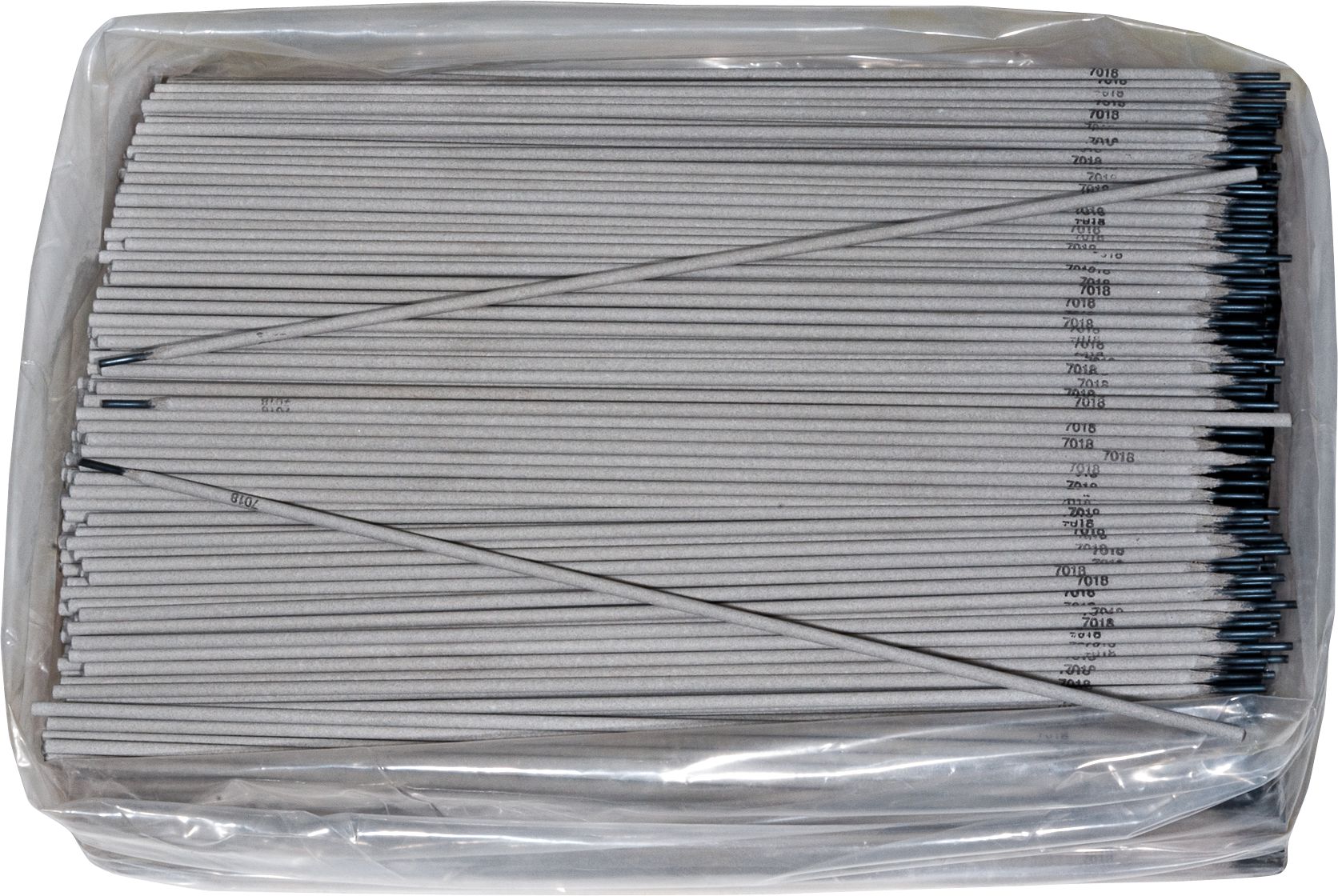

E7018 Mild/Carbon Steel Stick Electrode 1/8"

Couldn't load pickup availability

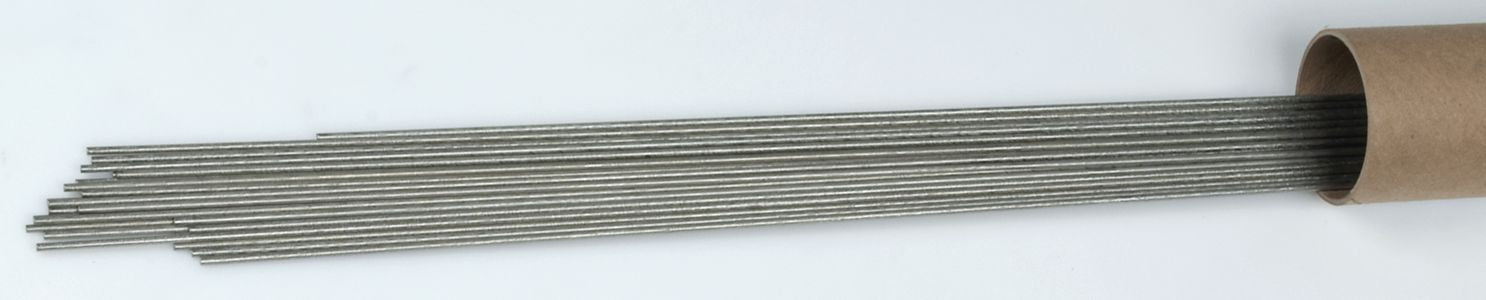

211 Cast Iron TIG Wire 3/32"

Couldn't load pickup availability

E7018 Mild/Carbon Steel Stick Electrode 3/32"

Couldn't load pickup availability

Product Description

Highly versatile alloys for all weldable types of aluminum including sheet, forgings, extrusions and castings.Superior Advantages

• Stable, quiet arc with no undercutting

• Good corrosion resistance

Tensile Strength: 35,000 PSIPolarity: DC Reverse

Usage ProcedureMaintain the shortest arc possible, using DC reverse polarity only. On large heavy sections, preheating to 400°F (204°C) will produce faster, flatter deposit with no splatter. Electrode should be held almost perpendicular and use a rapid stringer or weaving technique with a backwhip at the crater. Bevel pieces 75° on sections 1/8" (3.2mm) or thicker.

Technical Specifications

| Item#: | CW1039 |

|---|---|

| Welding Process | Stick |

| Type | Flux Coated |

| Diameter | 1/8 " |

| Tensile Strength | 35,000 PSI |

| Base Metal | Aluminum |

| Polarity | DCRP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | Yes |

| Weight: | 2.0 lb |

Product Restrictions

California Proposition 65: Not Applicable

www.P65Warnings.ca.gov