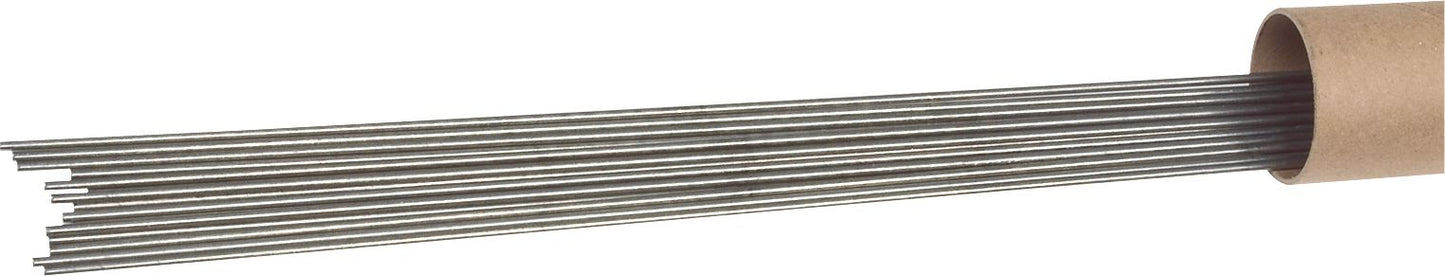

211 Cast Iron TIG Wire 1/8"

(Pack of

2.0)

All-position welding for any type of weldable cast iron repair and cast iron to steel.

Superior Advantages

• High strength welds

• Fully machinable

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

Tensile Strength: Up to 60,000 PSIHardness: 185 – 240 BHNPolarity: DC StraightGas: 100% Ar

Soft, ductile (copper/nickel) TIG filler wire provides excellent elongation for crack sensitive cast iron repairs. Excellent machinability and sealing properties for repairs on cylinder heads, blocks and thin castings such as water jackets.

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage ProcedureUse DC straight polarity. Stringer beads are recommended.

Couldn't load pickup availability

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov

Frequently Bought Together

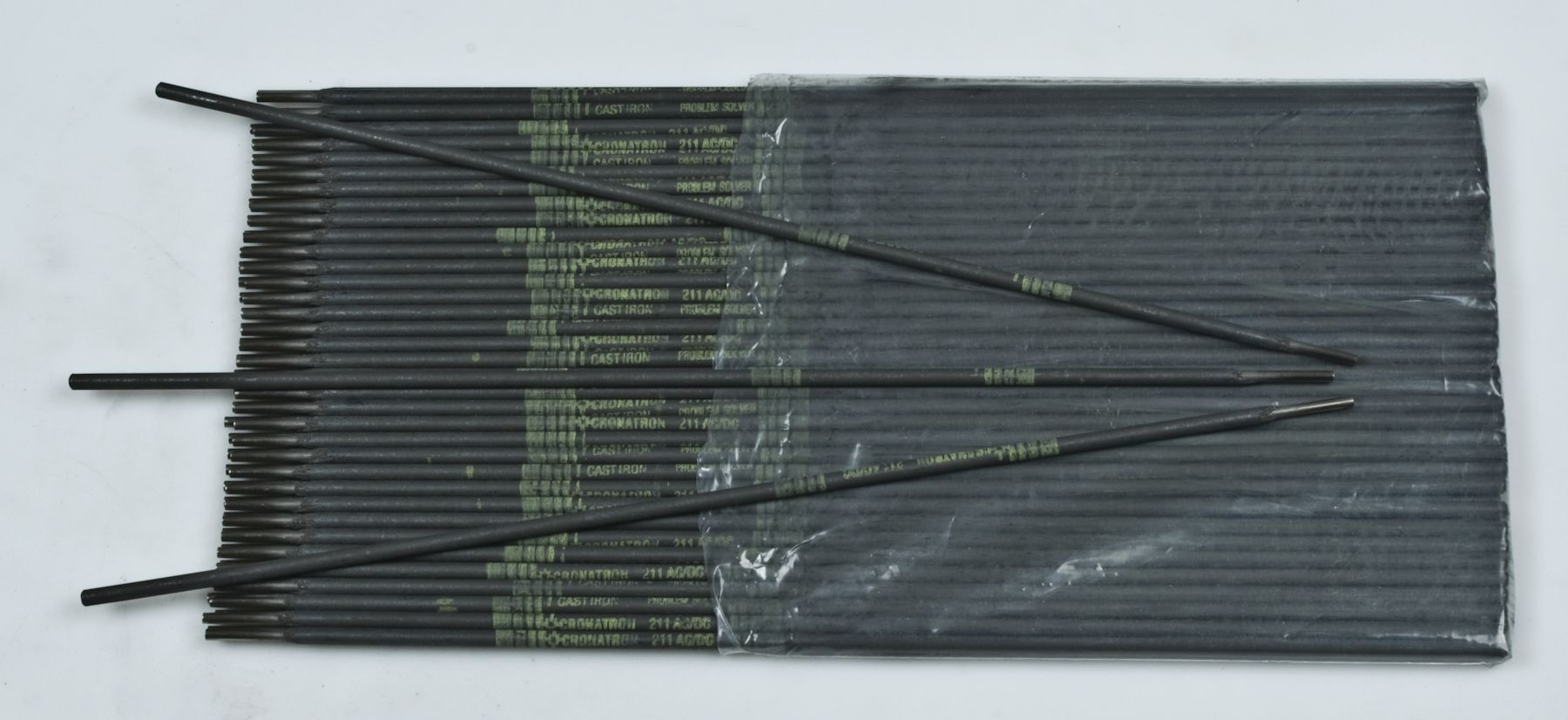

211 Cast Iron Stick Rod Electrode 1/8"

Couldn't load pickup availability

Engine Under Cover Drive Rivet Plastic 7mm Hole

Couldn't load pickup availability

Woven Polyester Electrical Tape 19mm x 25m

Couldn't load pickup availability

Fender Apron Drive Rivet 8mm Hole

Couldn't load pickup availability

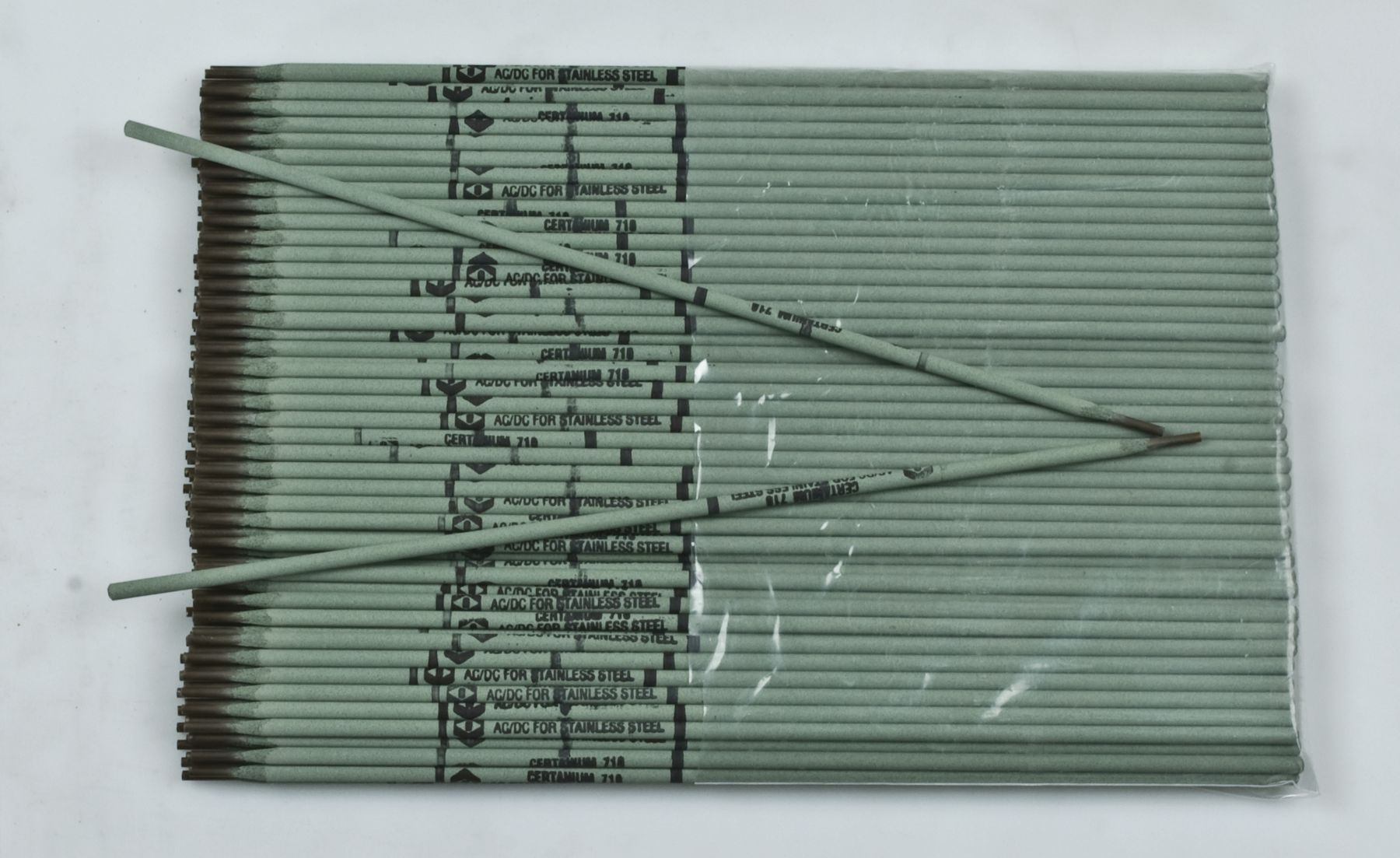

710 Stainless Steel Electrode 3/32"

Couldn't load pickup availability

Heat Stick 250F Degrees

Couldn't load pickup availability

Heat Stick 650F Degrees

Couldn't load pickup availability

192050 Plasma Cutting Shield Cup

Couldn't load pickup availability

9-6501 Plasma Cutting Tip

Couldn't load pickup availability

9-6004 Plasma Cutting Shield Cup

Couldn't load pickup availability

Product Description

All-position welding for any type of weldable cast iron repair and cast iron to steel.Superior Advantages

• High strength welds

• Fully machinable

• Pass-over-pass welding to save time

• All-position welding may eliminate the need to dismantle equipment to perform repairs

Tensile Strength: Up to 60,000 PSIHardness: 185 – 240 BHNPolarity: DC StraightGas: 100% Ar

Soft, ductile (copper/nickel) TIG filler wire provides excellent elongation for crack sensitive cast iron repairs. Excellent machinability and sealing properties for repairs on cylinder heads, blocks and thin castings such as water jackets.

Typical Applications

• Pump and bearing housings

• Cylinder blocks and heads

• Machine bases

• Manifolds and exhaust systems

Usage ProcedureUse DC straight polarity. Stringer beads are recommended.

Technical Specifications

| Item#: | CW1903 |

|---|---|

| Welding Process | TIG |

| Type | Solid |

| Diameter | 1/8 " |

| Length | 36 " |

| Tensile Strength | 60,000 PSI |

| Base Metal | Cast Iron |

| Hardness | 185-240 BHN |

| Shielding Gas | 100% Ar |

| Polarity | DCSP |

| UNSPSC #: | 23271810 |

| TAA Compliant: | No |

| Weight: | 3.0 lb |

Product Restrictions

California Proposition 65: WARNING: Cancer -

www.P65Warnings.ca.gov